ARCHIVED – Many Islands Pipe Lines (Canada) Limited: Hazard and Risk Assessment as related to Emergency Management – OF-Surv-OpAud-Ml82-2017-2018 01

This page has been archived on the Web

Information identified as archived is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please contact us to request a format other than those available.

OF-Surv-OpAud-Ml82-2017-2018 01

24 May 2018

Mr. Ken From

President and CEO

SaskEnergy Incorporated

(Many Islands Pipe Lines (Canada) Limited)

1000-1777 Victoria Avenue

Regina, SK S4P 4K5

Email:

Dear Mr. From:

- National Energy Board (NEB or Board)

Final Audit Report for Review (Audit)

Many Islands Pipe Lines (Canada) Limited

On 3 October 2017, the Board informed Many Islands Pipe Lines (Canada) Limited (MIPL(C)L) of its intent to audit its NEB regulated facilities. The findings of the Audit are based upon an assessment of whether MIPL(C)L was compliant with the regulatory requirements contained within:

- the National Energy Board Act and its associated regulations, including;

- the National Energy Board Onshore Pipeline Regulations;

- Any conditions contained within applicable Board certificates or orders issued by the Board (collectively referred to as, Legal Requirements).

MIPL(C)L was required to demonstrate the adequacy and effectiveness of the methods it has selected and employed within its management system and programs to meet the regulatory requirements listed above. Throughout this audit, the Board evaluated Emergency Management and related inputs and outputs as captured in sub-element 2.1 Hazard Identification, Risk Assessment and Control of the NEB Management System and Protection Program Audit Protocol.

The Board has enclosed its Final Audit Report for MIPL(C)L. The Board will make the Final Audit Report public and it will be posted on the Board’s website.

Corrective and Preventative Action Plan (CAPA)

MIPL(C)L is required to file a Corrective and Preventive Action (CAPA) Plan for Board approval on or before 25 June 2018, which describes the methods, timing and rationales for addressing the Non-Compliant findings identified through this audit. The Board has attached a CAPA Plan template document for MIPL(C)L to follow while it prepares its CAPA Plan for submission. An electronic copy should be requested by contacting the Board’s Lead Auditor, as identified below.

The Board will make the CAPA Plan public and will continue to monitor and assess all of MIPL(C)L’s corrective actions with respect to this audit until they are fully implemented. The Board will also continue to monitor the implementation and effectiveness of MIPL(C)L’s management system and programs through targeted compliance verification activities as a part of its on-going regulatory mandate.

If you require any further information or clarification, please contact Marnie Sparling, Lead Auditor, at 403-629-6394.

Yours truly,

Original signed by

Sheri Young

Secretary of the Board

c.c.

Many Islands Pipe Lines (Canada) Limited:

Hazard and Risk Assessment as related to Emergency Management

File: OF-Surv-OpAud-Ml82-2017-2018 01

1000-1777 Victoria Avenue

Regina, Saskatchewan

S4P 4K5

24 May 2018

Executive Summary

In accordance with Section 49(3) of the National Energy Board Act (NEB Act), the National Energy Board (NEB or the Board) conducted a compliance audit of SaskEnergy Incorporated’s federally regulated assets, Many Islands Pipe Lines (Canada) Limited (MIPL(C)L). The audit took place between 3 October 2017 and 13 March 2018.

This audit is one in a series of focused audits that the Board is conducting to examine specific components of companies’ emergency management programs related to the identification and mitigation of hazards. The key objective of this audit was to verify that MIPL(C)L was developing the fundamental components of its Emergency Management (EM) Program in order to mitigate the hazards and risks associated with its facilities and activities. In particular, this audit examined the identification and control of hazards within MIPL(C)L’s:

- Emergency management program;

- Emergency procedures manuals;

- Emergency related contingency and/or site-specific plans; and

- Emergency exercise programs.

The Board conducted the audit using the audit protocols attached in 1 of this report as they apply to MIPL(C)L’s hazard identification and analysis activities. The Board assessed whether the company’s documentation, processes and activities complied with the legal requirements contained within:

- The National Energy Board Act (NEB Act);

- The National Energy Board Onshore Pipeline Regulations (OPR); and

- Canadian Standards Association (CSA) Standard Z662 – 15 – Oil and Gas Pipeline Systems, as referenced in OPR section 4 (CSA Z662-15).

There were 12 items listed in the audit protocol. Of those, there were six in which the Board did not identify any compliance issues and six that were found to be non-compliant.

In its audit, the Board found non-compliances as summarized below.

- Although the company demonstrated that its Emergency Management (EM) Program related documentation was reviewed, revised and maintained, it did not demonstrate that it was subject to a consistent document control process that meets the requirements of OPR 6.5 (1) (o) (Refer to Appendix I Protocol Item AP-05);

- The company demonstrated that it has developed and implemented several activities to identify hazards and potential hazards related to health and safety. However, it did not demonstrate how hazards and potential hazards that would impact the EM Program were identified and reported. In addition, MIPL(C)L did not demonstrate how the outputs of the hazard identification activities are analyzed for the ongoing maintenance of the EM Program including the manuals, exercises and contingency plans. (Refer to Appendix I Protocol Item AP-07);

- The company did not provide a hazard inventory that reflects the hazards and potential hazards specifically related to the MIPL(C)L facilities. (Refer to Appendix I Protocol Item AP-08)

- The company did not demonstrate that it applies its process for evaluating risks to any hazards and potential hazards identified within in EM Program (Refer to Appendix I Protocol Item AP-09);

- The company did not demonstrate that it has established and implemented a documented, explicit methodology or process to be followed for the development of controls and for communicating those controls within the EM Program. (Refer to Appendix I Protocol Item AP-10); and

- The company did not demonstrate that it has established and implemented a process for developing contingency plans for abnormal events that may occur during emergency situations. (Refer to Appendix I Protocol Item AP-11).

The Board notes that, at the time of the audit, MIPL(C)L was in the midst of implementing a Unified Management System (UMS) which introduced overarching processes for its protection programs including its EM Program. As a result, some processes had not been implemented for three months, which is the Board’s minimum period for a process to be considered established. Non-compliances were also identified in cases where MIPL(C)L did not demonstrate a documented process or output with linkages between its management system level hazard identification and evaluation activities and its program level controls such as its EM Manual and EM exercises.

Notwithstanding the above noted non-compliances, the Board’s audit verified that MIPL(C)L had implemented an EM Program with the components to mitigate the hazards and risks associated with its NEB regulated assets facilities, albeit not documented to the extent or in the manner required by the OPR. Furthermore, the Board also noted that MIPL(C)L’s EM Program is well-integrated with and supported by SaskEnergy/TransGas’s EM Program for the province- wide distribution system which has established ties to the provincial emergency response organizations and requirements.

Within 30 days of the Final Audit Report being issued, MIPL(C)L must develop and submit a Corrective and Preventive Action Plan (CAPA Plan) for Board approval. The CAPA Plan must outline how MIPL(C)L intends to resolve the non-compliances identified by this audit and to prevent recurrence and the timeline in which corrective and preventive actions will be completed. The Board will verify that the corrective and preventive actions are completed in a timely manner. The Board will continue to monitor the implementation and effectiveness of MIPL(C)L’s management system and programs through targeted compliance verification activities as part of its ongoing regulatory mandate.

Table of Contents

- Cover Letter

- Executive Summary

- 1.0 Introduction

- 2.0 Audit Protocol Design

- 3.0 Company Overview

- 4.0 Summary of Audit Findings

- 5.0 Conclusion

- 6.0 Corrective Action Plan Submission

- Appendix I: Hazard and Risk Assessment Audit as they relate to Emergency Management – Audit Assessment Tables

- Appendix II: NEB Purpose and Audit Framework

- Appendix III: Terminology and Definitions

- Appendix IV: Abbreviations

- Appendix V: Documents and Records Reviewed

- Appendix VI: TransGas/SaskEnergy (Many Islands Pipe Lines (Canada) Limited) – Company Representatives Interviewed

1.0 Introduction

In accordance with Section 49(3) of the National Energy Board Act (NEB Act), the National Energy Board (NEB or the Board) conducted a compliance audit of SaskEnergy Incorporated’s federally regulated assets, Many Islands Pipe Lines (Canada) Limited (MIPL(C)L). An overview of the audit process and an explanation of definitions and abbreviations can be found in Appendices II – IV.

1.1 Audit Objective

The objective of this series of audits was to verify that selected companies are developing key components of its required Emergency Management (EM) Program consistent with the hazards and associated risks of its facilities and activities. The key components of the EM Program that were included in this audit are:

- Emergency procedures manuals;

- Emergency related contingency and/or site-specific plans; and

- Emergency exercise programs.

1.2 Audit Scope

The audit scope included the requirements of the National Energy Board Onshore Pipeline Regulations (OPR) primarily focusing on, but not limited to OPR sections 32-35 and 6.5 (1) (c), (d), (e), (f) and (t) as they relate to the EM Program.

1.3 Audit Criteria

The Board assessed whether MIPL(C)L’s documentation, processes and activities complied with the legal requirements contained within:

- The NEB Act;

- The OPR;

- Canadian Standards Association (CSA) Standard Z662 – 15 – Oil and Gas Pipeline Systems (CSA Z662-15); and

- MIPL(C)L’s policies, programs, practices and procedures.

2.0 Audit protocol design

The focused audit protocol used for this series of audits is based on the management system requirements found in Sections 6.1 to 6.6 of the OPR as well as other requirements within the scope of the audit. Audit Protocol (AP) questions were assigned a numbering system from AP 01 to AP-12.

- AP 01- 06 and AP 12 were used to audit the company’s compliance of its EM Program activities. The resulting inputs and outputs are linked to the management system processes required by the OPR.

- AP 07-11 were used to audit the company’s implementation of its EM Program with regards to the processes, procedures and standards that it identifies as being part of its management system and protection programs.

3.0 Company Overview

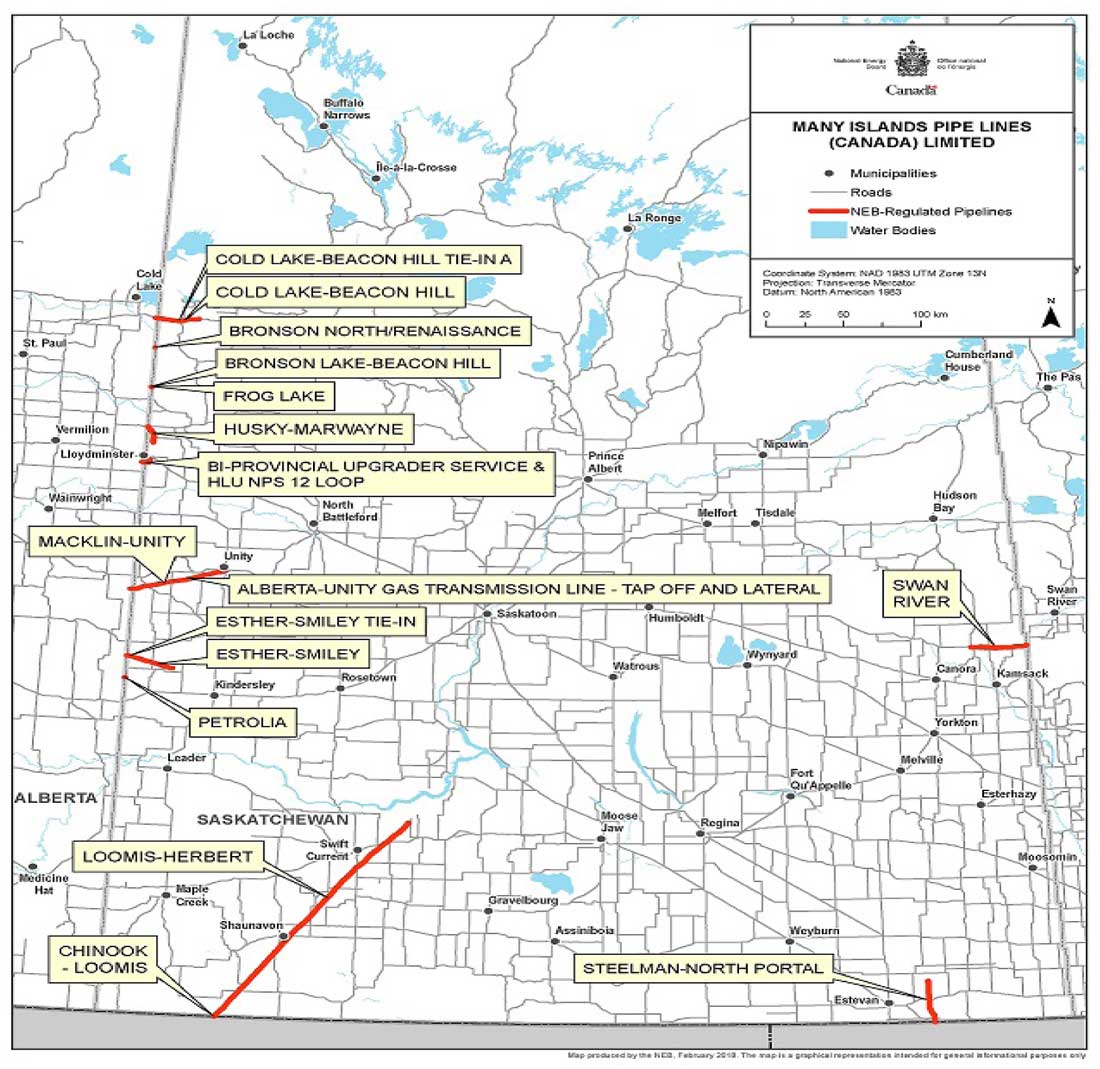

Many Islands Pipe Lines (Canada) Limited (MIPL(C)L) is a wholly owned subsidiary of SaskEnergy Incorporated, a provincial Crown corporation in the Province of Saskatchewan engaged in transportation and storage of natural gas. The MIPL(C)L system consists of 17 pipelines, totaling 446 kilometers. These pipelines are used for the interprovincial and international transportation of natural gas.

Within the above corporate structure, TransGas owns and operates the transmission utility for SaskEnergy, and has the exclusive legislated franchise to transport natural gas within the province of Saskatchewan. TransGas and MIPL(C)L 's interconnections with other transmission systems provide access to Manitoba, eastern Canadian and United States markets for Saskatchewan, Alberta and United States-sourced gas supplies. The MIPL(C)L pipeline system is regulated by the NEB and is subject to the NEB Act and associated regulations.

MIPL(C)L has entered into a Service Agreement with TransGas Limited, whereby TransGas provides the following services to MIPL(C)L:

- Management Services

- Accounting Services

- Construction of Facilities

- Engineering Services

- Legal and Regulatory Services

- Day to Day Pipeline System Operations and Maintenance

- Receipt and Processing of Gas Nominations

- Electronic Business Services

4.0 Summary of Audit Findings

Reference |

OPR Requirement |

Status |

|---|---|---|

AP01 1.1 Policy and Commitment Statement |

OPR s. 32 (1): A company shall develop, implement and maintain an emergency management program that anticipates, prevents, manages and mitigates conditions during an emergency that could adversely affect property, the environment or the safety of workers or the public. Status: No issues of non-compliance identified. |

|

OPR s. 32 (1.1): The company shall develop an emergency procedures manual, review it regularly and update it as required. Status: No issues of non-compliance identified. |

||

AP02 1.1 Policy and Commitment Statement |

OPR s. 6.3 (1): The company shall establish documented policies and goals for meeting its obligations under section 6, including (b) goals for the prevention of ruptures, liquid and gas releases, fatalities and injuries and for the response to incidents and emergency situations. Status: No issues of non-compliance identified. |

|

AP03 3.3 |

OPR s. 6.5 (1)(i): establish and implement a process for identifying and managing any change that could affect safety, security or the protection of the environment, including any new hazard or risk, any change in a design, specification, standard or procedure and any change in the company’s organizational structure or the legal requirements applicable to the company; Status: No issues of non-compliance identified. |

|

AP04 3.4 Training and Competence |

OPR s. 6.5 (1)(j): establish and implement a process for developing competency requirements and training programs that provide employees and other persons working with or on behalf of the company with the training that will enable them to perform their duties in a manner that is safe, ensures the security of the pipeline and protects the environment; Status: No issues of non-compliance identified. |

|

AP05 3.6 |

OPR s. 6.5 (1)(o): establish and implement a process for preparing, reviewing, revising and controlling those documents, including a process for obtaining approval of the documents by the appropriate authority;

Status: Non-Compliant |

|

AP06 4.1 Inspection Measurement and Monitoring |

OPR s. 6.5(1)(u): establish and implement a process for inspecting and monitoring the company’s activities and facilities to evaluate the adequacy and effectiveness of the programs referred to in section 55 and for taking corrective and preventive actions if deficiencies are identified; Status: No issues of non-compliance identified. |

|

AP07 2.1 Hazard ID |

OPR s. 6.5 (1)(c): establish and implement a process for identifying and analyzing all hazards and potential hazards;

Status: Non-Compliant |

|

AP08 2.1 Hazard ID |

OPR s. 6.5 (1)(d): establish and maintain an inventory of the identified hazards and potential hazards;

Status: Non-Compliant |

|

AP09 |

OPR s. 6.5 (1)(e): establish and implement a process for evaluating and managing the risks associated with the identified hazards, including the risks related to normal and abnormal operating conditions;

Status: Non-Compliant |

|

AP10 2.1 Hazard ID |

OPR s. 6.5(1)(f): establish and implement a process for developing and implementing controls to prevent, manage and mitigate the identified hazards and the risks and for communicating those controls to anyone who is exposed to the risks;

Status: Non-Compliant |

|

AP11 3.2 |

OPR s. 6.5 (1)(t): establish and implement a process for developing contingency plans for abnormal events that may occur during construction, operation, maintenance, abandonment or emergency situations;

Status: Non-Compliant |

|

AP12 4.1 Inspection Measurement and Monitoring |

CSA Z662-15 – clause 10.5.2.1 – CSA Z662-15 – clause 10.5.2.4 Status: No issues of non-compliance identified. |

|

5.0 Conclusion

This focused audit was designed to examine particular aspects of EM Programs related to the identification and mitigation of hazards using the 12 protocol items listed in the attached audit protocol. In the case of MIPL(C)L, the Board identified seven protocol items without any compliance issues; and five where non-compliance with the requirements was noted.

The Board notes that, at the time of the audit, MIPL(C)L was in the midst of implementing a Unified Management System (UMS) which introduced overarching processes for its protection programs including its EM Program. As a result, some processes had not been implemented for 3 months, which is the Board’s minimum period for a process to be considered established. Non-compliances were also identified in cases where MIPL(C)L did not demonstrate a documented process or output with linkages between its management system level hazard identification and evaluation activities and its program level controls such as its EM Manual and EM exercises.

Notwithstanding the above noted non-compliances, the Board’s audit verified that MIPL(C)L had implemented an EM Program with the components to mitigate the hazards and risks associated with its NEB regulated assets facilities, albeit not documented to the extent or in the manner required by the OPR. Furthermore, the Board also noted that MIPL(C)L’s EM Program is well-integrated with and supported by SaskEnergy/TransGas’s EM Program for the province-wide distribution system which has established ties to the provincial emergency response organizations and requirements.

6.0 Corrective Action Plan Submission

MIPL(C) L is required to develop and corrective and preventive action plan (CAPA Plan) to rectify the deficiencies noted in this report for Board approval within 30 days of the date of this report. The CAPA Plan must follow the Board’s established CAPA Plan template. The Board will verify the implementation of the CAPA Plan as part of its on-gong compliance verification activities.

The Board will post the Final Audit Report and the approved CAPA Plan on its website.

Appendix I: Hazard and Risk Assessment Audit as they relate to Emergency Management – Audit Assessment Tables

Topic: National Energy Board Onshore Pipeline Regulations: Section 32 (1) NOTE: Given the scope of this audit, the elements and regulatory requirements examined will be related to the hazards and potential hazards that would initiate emergency or contingency responses. |

||

Regulatory Requirement: OPR s. 32 (1): A company shall develop, implement and maintain an emergency management program that anticipates, prevents, manages and mitigates conditions during an emergency that could adversely affect property, the environment or the safety of workers or the public 32 (1.1): The company shall develop an emergency procedures manual, review it regularly and update it as required. |

||

Criteria Element 1: Requirements:

|

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-01 |

Can the company demonstrate that it has developed, implemented, and maintains an emergency management program that anticipates, prevents, manages and mitigates conditions during an emergency? Can the company demonstrate that it has developed an emergency procedures manual that anticipates, prevents, manages and mitigates conditions during an emergency? Can the company demonstrate that it has reviewed the emergency procedures manuals on a regular basis and update the manuals as required? |

No issues of non-compliance identified. |

Summary Assessment Notes |

||

Unified Management System At the time of the audit, MIPL(C)L was implementing a Unified Management System (UMS) which is outlined in the Unified Management System framework document. This document states that the purpose of the UMS includes integrating the company’s operational activities and technical systems with its management of human and financial resources to enable the company to meet its obligations. Further, it states that the UMS ensures coordination between its programs including its emergency management program, integrity management program, pipeline control system, safety management program, security management program, environmental protection program and damage prevention program. The UMS has been structured based on current operations, systems, processes and procedures in place, and establishes the processes used by the company for the safety and security of the public and the company’s employees, the safety and security of the pipeline, and the protection of property and the environment. The UMS drives operational controls as a means to ensure that the obligations of the UMS are met. This is done by requiring the establishment, implementation and maintenance of appropriate procedures and operating criteria, including those required to address abnormal operating conditions. The Asset Management System outlined within UMS, is a coordinated set of programs that addresses the company's asset management responsibilities in a manner that supports the achievement of the objectives of the UMS. The Asset Management System is comprised of 16 programs, one of which is the Corporate Emergency Management Program. Corporate Emergency Management Program (CEMP) MIPL(C)L is governed by a Corporate Emergency Management Program (CEMP) which also applies to all emergency planning and response activities within SaskEnergy. According to the CEMP Program Manual, the “The CEMP provides specific direction to functional areas of the company which are:

The CEMP incorporates procedures that are to be used as controls to mitigate and respond to threats as listed within the CEMP document. The CEMP methodology separates “threats” into pre-event (mitigation and preparedness) and post-event (response and recovery). Preparedness includes; forecasting the types of emergencies that could occur and the people, equipment, organization and training that would be required to respond effectively. Emergency Procedures Manual The Emergency Response Manual that applies to MIPL(C)L includes details of each facility operated by MIPL(C)L, schematics, guidelines for response and reporting and an emergency contact list for each pipeline. The manual contains procedures to be followed for events such as responding to chemical spills, odour releases or spills, and civil disturbances. In accordance with the annual review process, Section 6 of the manual lists the reviews and revisions of the manual since 2015. The Board notes that these updates have occurred in accordance with the requirements of OPRs. 32 (1.1) which states: “The company shall develop an emergency procedures manual, review it regularly and update it as required.” Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation the above requirements. Although no issues of non-compliance are noted with OPR s.32 (1.1), section AP05 of this report reviews the lack of a documented management system level document control process as required by s. 6.5 (1) (o) being applied to the Emergency Response Manual. |

||

Topic: Management System Sub Element 2.3 – Goals, Objectives and Targets NOTE: Given the scope of this audit, the elements and regulatory requirements examined will be related to the hazards and potential hazards that would initiate emergency or contingency responses. |

||

Regulatory Requirement: OPR s. 6.3 (1): The company shall establish documented policies and goals for meeting its obligations under section 6, including (b) goals for the prevention of ruptures, liquid and gas releases, fatalities and injuries and for the response to incidents and emergency situations. |

||

Criteria Element 1: Requirement for the company to demonstrate that it has established documented goals for the prevention of ruptures, liquid and gas releases, fatalities and injuries and for the response to incidents and emergency situations. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-02 |

Can the company demonstrate that it has developed goals related to its hazards and risks for its Emergency Management Manuals, contingency plans and Emergency Management exercises? |

No issues of non-compliance identified. |

Assessment Notes |

||

MIPL(C)L adheres to an Emergency Management Policy which states that the company shall, through its emergency procedures, respond to all emergencies involving its facilities and service to its customers. The policy states that procedures contained within the company (Emergency Response) manual will be followed and applied as necessary, depending on the nature of the incident. According to the policy for Internal Reporting of Hazards, Incident and Near Misses, workers are encouraged to identify hazards, incidents and near misses at their work site. The policy also includes a commitment to protect employees from any form of discipline related to the identification of hazards, incidents and near-misses in the work place. The EM Program goals are described in the “Set Annual Program/Plan Goals, Objectives, and Targets (GOTs)” document which outlines expectations and requirements needed to manage the activities that align with the corporate direction and priorities. This document states one of its purposes as, “to establish goals for the prevention of ruptures, liquid and gas releases, fatalities and injuries and for the response to incidents and emergency situations”. MIPL(C)L provided the 2017 CEMP Goals and Objectives document, which describes seven objectives. During the audit, MIPL(C)L stated that these objectives and targets are developed by the Executive Steering Committee and are reviewed quarterly to monitor performance in meeting established targets. In addition, the SaskEnergy/TransGas Pipeline Integrity Management Program states that, “the overall goal of pipeline integrity is to ensure the safety of the public and environment.” The Integrity Management Policy statement specifically includes goals for the prevention of ruptures, releases, fatalities and injuries. Further, the Integrity Management Program document includes a statement that Corporately, the vision for pipeline incidents is; zero ruptures, zero fatalities, and zero injuries. As part of the CEMP, SaskEnergy/TransGas Engineering, has developed a functional level plan for the programs under the CEMP umbrella. This plan includes a listing and status update for EM Program objectives and targets for 2016, and plans for 2017 and for the next four years (2018 through to 2021). The plan directs that performance measures with objectives for other plans and controls will be reported to the CEMP Steering Committee and the Executive. SaskEnergy Operations has developed response time expectations for the federally regulated transmission system, which are aligned with availability of staff to respond to emergencies. MIPL(C)L indicated that for locations on its transmission system (outside of manned stations), it is expected that personnel will respond to the locations within 1.5 hours, more than 95% of the time. Response time expectations are also outlined for manned locations. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. |

||

Topic: Management System Sub Element 3.3 – Management of Change (MOC) |

||

Regulatory Requirement: OPR s. 6.5 (1)(i): establish and implement a process for identifying and managing any change that could affect safety, security or the protection of the environment, including any new hazard or risk, any change in a design, specification, standard or procedure and any change in the company’s organizational structure or the legal requirements applicable to the company; |

||

Criteria Element 1: Requirement for the company to establish and implement a process for identifying and managing any change that could affect safety, security or the protection of the environment, including any new hazard or risk. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-03 |

Can the company demonstrate that it has established and implemented a process for identifying and managing any change that could affect safety, security or the protection of the environment, including any new hazard or risk, as it relates to the ongoing development of Emergency Management Manuals, Contingency Plans and Emergency Management Exercises? |

No issues of non-compliance identified. |

Assessment Notes |

||

As part of the UMS implementation, MIPL(C)L adheres to a MOC procedure and a MOC process document, each of which outline expectations and requirements to manage the critical activities necessary to minimize the risks associated with permanent or temporary changes. The process as stated is to be used to, “identify and manage changes that could affect people, property, the pipeline system and the environment. This includes any new hazard or risk, any change in design, specification, standard or procedure”. As outlined in the Process Safety Management Program, the Program plans and manages the MOC process for process safety at the operational and facility change level. The MIPL(C)L Emergency Response Manual, specifies that, “ any errors, omissions or requests for revisions will be documented through the Management of Change (MOC) process”. During the audit, MIPL(C)L provided records to demonstrate the MOC process was recently applied to revise the MIPL(C)L Emergency Response Manual as a result of a disposition of an asset. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. |

||

Topic: Management System Sub Element 3.4 – Training, Competence and Evaluation |

||

Regulatory Requirement: OPR s. 6.5 (1)(j): establish and implement a process for developing competency requirements and training programs that provide employees and other persons working with or on behalf of the company with the training that will enable them to perform their duties in a manner that is safe, ensures the security of the pipeline and protects the environment; |

||

Criteria Element 1: Requirement for the company to establish and implement a process for developing competency requirements and training programs that provide employees and others working with or on behalf of the company with the training that will enable them to perform their duties in a manner that is safe, ensures the security of the pipeline and protects the environment. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-04 |

Can the company demonstrate that it has a process for developing competency requirements and training programs as required for, and within, the Emergency Management Program? |

No issues of non-compliance identified. |

Assessment Notes |

||

SaskEnergy/TransGas has developed a Competency Assessment Plan (CAP) which is controlled by the training group within the Human Resources department. This plan provides a standardized approach to ensure workers are qualified and competent to perform activities or tasks on the company’s pipeline systems including the MIPL(C)L facilities. This CAP includes details to what needs to be completed in developing qualification plans and outlines responsibilities to be considered to ensure proper training is administered and that an evaluation (and re-evaluation) of knowledge and an evaluation of competency for activities or tasks is completed. Specific evaluation methods are provided to evaluate workers performing a specific task or activity. These methods include written and oral examinations, and observation/evaluation of performance; on the job, during on the job training, and during simulations. CAPs for various operational tasks related to emergency response including:

During the audit, MIPL(C)L stated that emergency response exercises are considered to be effective tools for training staff for response and to evaluate their competency in responding to emergency events. Over the 2016-2017 year, 30 tabletop exercises completed throughout the company, two of which were specific to the transportation system. In addition, two of the three simulation exercises were specific to MIPL(C)L. It was also noted that a mock exercise is scheduled to be completed for MIPL(C)L in 2018. MIPL(C)L demonstrated through documentation provided that it has developed an Operations Training Matrix. This matrix identifies required training courses for positions within the Operations team. Included within these courses is the Online Emergency Response 101 Course which is mandatory for most positions. Incident Command System (ICS) 100 and ICS 200 are also included within the training matrix; however, these courses are only considered mandatory for selected positions. Based on documentation reviewed, the NEB noted that:

The NEB was advised during interviews that the Human Resources department has recently included emergency management training within its Learning Management System. This change will represent an improvement to existing practice as going forward. The system will monitor and report on training requirements and certification expiries. According to MIPL(C)L, contract personnel do not have responsibilities related emergency response on behalf of the company. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. |

||

Topic: Management System Sub Element 3.6 – Documentation and Document Control |

||

Regulatory Requirement: OPR s. 6.5(1)(o): establish and implement a process for preparing, reviewing, revising and controlling those documents, including a process for obtaining approval of the documents by the appropriate authority; |

||

Criteria Element 1: Establish and implement a process for preparing, reviewing and controlling documents. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-05 |

Can the company demonstrate that it has established and implemented a process for preparing, reviewing and controlling documents and that it uses the process for the Emergency Management Manuals and Contingency Plans? |

Non-Compliant |

Assessment Notes |

||

During interviews and document review, MIPL(C)L indicated that it adheres to the corporate UMS Documentation Management Procedure (DMP). First released in 2016, the DMP provides guidance on the preparation and maintenance of UMS related documentation and includes requirements of UMS documents to include identification of document owner, reviewer, and record of annual review(s) and updates. Direction includes guidelines for; creating, revising, reviewing, approving, and deleting UMS documents. According to the document, this procedure applies to Program, Plan and System owners and is to be applied to UMS controlled documents. During the audit, the NEB reviewed several management system level process documents that appeared to be subject to an overarching document management process in that they followed a prescribed style and demonstrated consistent review, revision and approval practices. Review of the MIPL(C)L Emergency Response Manual identified that it is version controlled on the CEMP SharePoint site – MIPL(C) L Emergency Response. Distribution of the document is primarily electronic through the SharePoint site where access to versions is based on site permissions. Additionally, it was identified that four (4) hard copies are provided to select recipients, including the NEB, and printouts are considered uncontrolled. Over the course of the audit, MIPL(C)L demonstrated that its Corporate Emergency Management Manual was subject to review, revision and updating when changes were required. The NEB noted, however, that the current review, approval and updating process is unique to the Emergency Manual and therefore MIPL(C)L did not demonstrate this document is subject to the overarching management system level DMP document control and approval process. The NEB reviewed other EM Program documentation to verify its conformance to the DMP and noted the following inconsistencies:

Given the inconsistencies noted between the EM documentation and the other management system documentation that was provided, the Board determined that MIPL(C)L has not consistently implemented a process for preparing, reviewing, revising and controlling those documents, including a process for obtaining approval of the documents by the appropriate authority for its EM Program documentation. Therefore, MIPL(C)L is in non-compliance with OPR s. 6.5 (1)(o) as it relates to its EM Program documentation. The Board requires that a CAPA Plan be developed to address this non-compliance. |

||

Topic: Management System Sub Element 4.1 – 1 Inspection, Measurement and Monitoring |

||

Regulatory Requirement: OPR s. 6.5(1)(u): establish and implement a process for inspecting and monitoring the company’s activities and facilities to evaluate the adequacy and effectiveness of the programs referred to in section 55 and for taking corrective and preventive actions if deficiencies are identified; |

||

Criteria Element 1: Establish and implement a process for inspecting and monitoring the company’s activities to evaluate the adequacy and effectiveness of the Emergency Management Manuals, contingency plans and exercises and for taking corrective and preventive actions if deficiencies are identified. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-06 |

Can the company demonstrate that it has established and implemented a process for inspecting and monitoring the company’s activities to evaluate the adequacy and effectiveness of the Emergency Management Program and for taking corrective and preventive actions if deficiencies are identified? |

No issues of non-compliance identified. |

Assessment Notes |

||

During the audit, MIPL(C)L discussed several activities it conducts to monitor and evaluate the effectiveness of its EM Program. These activities include audits, emergency exercises and documented de-briefs for emergency events that required ICS. SaskEnergy/TransGas Audit Services is responsible for the internal audits of company processes and programs on a three-year basis. Audit Services completed an audit of the EM Program in 2016 to determine if the CEMP meets the requirements of the OPR. The final report was released 6 February 2017 containing one observation for correction. The issue was assigned to a Management Sponsor to develop an appropriate action plan to address identified gaps, with a due date of 31 March 2018. In this case, the action required updating emergency impact zones and lists for MIPL(C)L pipelines. According to MIPL(C)L, this action has been addressed. MIPL(C)L also evaluates and monitors the adequacy of its EM Program by using debriefs to capture lessons learned following events that required the activation of ICS. It was noted during the audit that SaskEnergy/TransGas runs various emergency management exercises throughout its system on a regular basis. These exercises include practices for gathering direct and indirect participant feedback that is incorporated into the update of EM procedures, EM training and when evaluating emergency response equipment. Emergency response exercises are documented and may include debriefings to identify deficiencies or possible improvements. The Board noted that the 2012 Mock Exercise identified several recommendations for consideration by EM Program management. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. |

||

Topic: Management System Sub Element 2.1 Hazards Identification, Risk Assessment and Control |

||

Regulatory Requirement: OPR s. 6.5 (1)(c): establish and implement a process for identifying and analyzing all hazards and potential hazards; |

||

Criteria Element 1: Requirement for the company to establish and implement a process for identifying and analyzing all hazards and potential hazards |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-07 |

Can the company demonstrate a process for identifying and analyzing all hazards and potential hazards |

Non-Compliant. |

Assessment Notes |

||

SaskEnergy/TransGas provided the Hazard Identification Process for review. This process is utilized throughout the organization for identifying hazards in the workplace and for operations. Once hazards are identified, employees use the REO (Report Everything Online) System to capture hazards, near misses and incidents. Within REO, each hazard is classified as personal, public, or as a process safety hazard. Hazards are then risk ranked, and corrective actions applied if risk cannot be managed immediately. Similar procedures are followed for near misses and incidents. The Policy for Internal Reporting of Hazards, Incident and Near Misses includes an expectation of workers to identify hazards, incidents and near misses. The Policy also states that “Management will review all documented reports and take appropriate action relative to the seriousness of the risk identified.” Further, all employees are encouraged to be actively observing their work places and work tasks to identify possible risks and to report these within the REO system. Hazards related to health and safety are also identified during:

The Field Level Risk Assessment is designed for employees to identify potential hazards that may exist for the task and assign the corresponding control to manage the hazards. Although the company demonstrated that it has implemented several hazard identification activities, it did not provide documentation to demonstrate how the hazards or potential hazards identified through the mechanisms are to be captured in REO, captured in a hazard inventory or analyzed for their application to the EM Program. For example, as part of the UMS, the Process Safety Management (PSM) Gap Registry and Management process outlines the methodology to identify hazards and perform standardized risk assessments, and provides corrective and preventive action items. The inputs of this process originate from monthly meetings with subject matter experts reviewing Process Safety incidents in REO, and long term action items from Root Cause analysis reports/incident investigations. Additionally, hazards are identified within the All Hazards Risk Assessment Process which describes the process of reviewing the Risk and Hazards inventory as well as defining the relevance and impact of those risks and hazards. In reviewing this document, the All Hazards Risk Assessment Process does not include a methodology or process to analyze hazards and potential hazards. As described above, MIPL(C)L conducts various hazard identification activities, especially with respect to worker safety. However, the company did not demonstrate that it has an explicit, systematic process to identify and analyze hazards and potential hazards related to the EM Program. Further, the company did not provide an explicit systematic documented process describing how outputs of the hazard identification various activities were integrated into or analyzed in the development and maintenance of the EM Program. As a result of the assessment, the Board has determined that MIPL(C)L is in non-compliance with OPR s.6.5 (1)(c). The Board requires that a CAPA Plan be developed to address this non-compliance. |

||

Topic: Management System Sub Element 2.1 Hazards Identification, Risk Assessment and Control |

||

Regulatory Requirement: OPR s. 6.5 (1)(d): establish and maintain an inventory of the identified hazards and potential hazards; |

||

Criteria Element 1: Requirement for the company to establish and maintain an inventory of the identified hazards and potential hazards; |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-08 |

Does the company have and maintain an inventory of the identified hazards and potential hazards |

Non-Compliant. |

Assessment Notes |

||

At the time of the audit, MIPL(C)L provided an All Hazards List for review as its inventory of hazards and potential hazards. This list includes threats and hazards categorized within nine threat groups including:

Within this list, each threat has been assigned a priority level and describes the consequence and likelihood of occurrence and whether or not there is a procedure in place at SaskEnergy to address the issue. The NEB could not confirm the origin of the document because it did not follow the SaskEnergy document control template and was therefore not dated or signed. Upon review of this All Hazard List, the NEB found that it does not constitute an inventory of identified hazards and potential hazards related to its federally regulated operations. Rather, this document appears to be a tool used in emergency response planning to verify that potential emergency event types that could impact provincial infrastructure have been accounted for, considered and mitigated where required by SaskEnergy. The NEB determined that the list does not meet the requirements of the OPR s. 6.5 (1)(d) because it does not contain all of the hazards and potential hazards related to federally regulated pipelines nor is it an output of the hazard identification process. MIPL(C)L also provided the All Hazards Risk Assessment Process. According to the document, its purpose is to describe the process of reviewing the Saskatchewan Risk and Hazard Inventory and define the relevance and impact of the risks and hazards SaskEnergy’s environment. A review of the document indicated that it does not include a methodology to be followed to complete these hazard assessments nor does it link the maintenance of an inventory of identified hazards and potential hazards for its federally regulated pipeline operations. Although MIPL(C)L provided a list of all-hazards, the Board determined that the list did not constitute an inventory of hazards and potential hazards related to its federally regulated pipeline facilities. In addition, MIPL(C)L did not provide documentation that describes the maintenance of this list or its function within or link to the MIPL(C)L EM Program, therefore it does not meet the requirements of the OPR s. 6.5 (1)(d). |

||

Topic: Management System Sub Element 2.1 Hazards Identification, Risk Assessment and Control |

||

Regulatory Requirement: OPR s. 6.5 (1)(e): establish and implement a process for evaluating and managing the risks associated with the identified hazards, including the risks related to normal and abnormal operating conditions; |

||

Criteria Element 1: Requirement for the company to establish and implement a process for evaluating and managing the risks associated with the identified hazards, including the risks related to normal and abnormal operating conditions |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-09 |

The company must have a documented process for evaluating and managing the risks associated with the identified hazards, including the risks related to normal and abnormal operating conditions; |

Non-Compliant |

Assessment Notes |

||

|

MIPL(C)L provided several documents that described the evaluation of risk occurring at the corporate and EM Program level. These documents included: 1. The All Hazards Risk Assessment Process According to MIPL(C)L, this process is used to review the provincially managed All Hazard List and assess the relevance and impact of the risks and hazards to determine levels of preparedness. However, as noted in AP-08 above, the document does not provide a specific, process describing the methodology to be followed to evaluate and manage the risks. In addition, as this document was released in October 2017, it did not meet the Board’s definition of established because it had not been in place for 90 days at the time of the audit. 2. The UMS Risk Assessment Process and Procedure This corporate level management system process describes the risk identification and assessment activities within the UMS. The purpose of this process is to help the organization apply a structured and collaborative approach to identify, assess and evaluate risks and determine controls in order to manage the risks appropriately. The Risk Assessment Process document includes 4 levels of risk. These are listed as:

A review of the documentation found that there was a lack of clarity as to what exactly would constitute a risk at each of these levels and how they are linked to one another. Following the review of these documents, the NEB could not determine how the UMS Risk Assessment Process identifies the risks at each of the levels or how it accounts for and integrates any identified hazards at the EM Program Level. 3. The Asset Life Cycle – Risk/Control Register This document is maintained by the company’s Internal Audit Services group. It identifies 16 high level risks to the company and includes a corresponding list of controls that are available to be applied to manage the risks to a level that is acceptable to the company. Further review of the document found that “the Inadequate capability to respond to an emergency” was the only risk on the Register directly related to the EM Program. MIPL(C)L did not provide records to demonstrate that this risk from the EM Program was the result of a risk evaluation process. Instead, MIPL(C)L indicated that this risk was added to the Register in 2014 in order to proactively evaluate the controls in place. Due to the fact that this risk was added to the Register without adhering to a process that includes the evaluation and management of identified hazards and potential hazards, the NEB determined that this document does not meet the requirements of the OPR. Conclusion Following the review of each of the documents outlined above, the Board has determined that although some evaluation of risks is occurring related to the EM Program, MIPL(C)L did not demonstrate that it has implemented a documented, systematic process for evaluating and managing the risks associated with identified hazards, including the risks related to normal and abnormal operating conditions. As a result of the above assessment, the Board has determined that MIPL(C)L is in non-compliance with OPR s. 6.5 (1)(e). The Board requires that a CAPA Plan be developed to address this non-compliance. |

||

Topic: Management System Sub Element 2.1 Hazards Identification, Risk Assessment and Control |

||

Regulatory Requirement: OPR s. 6.5(1)(f): establish and implement a process for developing and implementing controls to prevent, manage and mitigate the identified hazards and the risks and for communicating those controls to anyone who is exposed to the risks; |

||

Criteria Element 1: Requirement for the company to establish and implement a process for developing and implementing controls to prevent, manage and mitigate the identified hazards and the risks and for communicating those controls to anyone who is exposed to the risks; |

||

Assessed Area: Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-10 |

The company must have a documented process for developing and implementing controls to prevent, manage and mitigate the identified hazards and the risks and for communicating those controls to anyone who is exposed to the risks; |

Non-compliant |

Assessment Notes |

||

Process for developing and implementing controls At the corporate level, the UMS Process Safety Management Program document describes threats that relate to natural gas pipeline and distribution systems, and includes a variety of company and industry controls put in place to manage these threats. Risk Controls for Process Safety are owned and managed within the following programs:

For Emergency Management, the CEMP was developed to be an overarching coordinated approach between the emergency programs developed at various levels within the Company. The CEMP Manual “incorporates more than fifty control processes that are used to mitigate and respond to threats.” In the document, Appendix I lists fifty control that are used to mitigate and respond to the threats listed in Appendix II that reflect those listed in CSA-Z662-15. Following a review of the controls listed in Appendix I, the Board found that the list of controls appears to be based on the generally accepted hazards associated with gas facilities including:

The Board found that while the CEMP document includes a list of various activities, documents and organizations that could contribute to the control of a hazard or threat, the CEMP does not describe the process that was used to develop or maintain this list of controls. Furthermore, the document does not describe how the list of controls has been applied or evaluated to ensure that these controls are adequate for addressing the threats listed by category in Appendix II. Additionally, this list of threats is limited to the threat categories as outlined in CSA Z662-15, which are threats to the integrity of the facilities and would not be considered to be appropriately all inclusive of the hazards and risks that would normally pertain to an EM Program. For example, the list does not address all of the hazards and risks associated with any high consequence areas along the facility rights of way have been included or addressed. However, MIPL(C)L did not demonstrate that this list is the result of an established and implemented process to be followed for developing and implementing these controls that has been applied within the EM Program. While the CEMP document includes a list of various activities, documents and organizations that could contribute to the control of a hazard or threat, the CEMP does not describe the process that was used to develop or maintain this list of controls. Furthermore, the document does not describe and no records were provided to show how the list of controls has been applied or evaluated to ensure that these controls are adequate for addressing the threats listed by category in Appendix II. Communicating Controls During the audit, MIPL(C)L demonstrated several formal and informal methods to communicate controls related to emergency management to its staff including training, documented procedures, bulletins and information sharing. MIPL(C)L maintains a documented procedures library known collectively as the Construction, Operation and Maintenance Procedures (COMPs). The documented procedures library is known collectively as the Construction, Operation and Maintenance Procedures (COMPs). The Board noted that this library contains several documented procedures developed to address the hazards associated with incident response. In addition, MIPL(C)L demonstrated that it communicates hazards by issuing company-wide bulletins and notices when safety issues deemed significant arise. For example, Hazard Highlights are distributed to staff on a regular basis to communicate various hazards and the recommended associated controls. Another example that was provided for review was the Safety Bulletin which was sent to staff to communicate potential hazards related to not taking proper precautions when responding to incidents involving overpressures where controls such as valves may not function as designed. Staff safety meetings, tailgate meetings, and emergency exercise debriefs, are also forums where MIPL(C)L informs employees of controls that can be used if exposed to identified hazards or risks. With respect to the communication of hazards and controls to the public, MIPL(C)L provided documentation including records indicating that it did so through its Public Awareness Program. These included publications and brochures such as:

While MIPL(C)L demonstrated that it is communicating its controls to employees and members of the public who are exposed to the risks, it did not provide a process that ties the development and implementation of controls for the identified hazards and risks with the communication of those controls to anyone who is exposed to the risks. Conclusion Based on the assessment, the Board notes that MIPL(C)L has developed a generic list of controls that could be applied to identified threats. The Board also notes that MIPL(C)L demonstrated various means to communicate controls to those persons who may be exposed to these hazards or risks. However, the company did not demonstrate that it has established and implemented a documented, explicit process or processes for the development of appropriate controls based on identified hazards that includes communicating those controls within the EM Program. As a result of the assessment, the Board has determined that MIPL(C)L is in non-compliance with OPR s. 6.5 (1)(f). The Board requires that a CAPA Plan be developed to address this non-compliance. |

||

Topic: Management System Sub Element 3.2 Operational Control – Upset or Abnormal Conditions |

||

Regulatory Requirement: OPR s. 6.5 (1)(t): establish and implement a process for developing contingency plans for abnormal events that may occur during construction, operation, maintenance, abandonment or emergency situations.. |

||

Criteria Element 1: Requirement for the company to establish and implement a process for developing contingency plans for abnormal events that may occur during construction, operation, maintenance, abandonment or emergency situations. |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises. |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-11 |

The company must have a documented process to establish and implement a process for developing contingency plans for abnormal events that may occur during construction, operation, maintenance, abandonment or emergency situations. |

Non-Compliant |

Assessment Notes |

||

During interviews and through document review, MIPL(C)L indicated that it includes contingency planning within its emergency response activities as part of its execution of the Incident Command System (ICS). In addition, there are references to contingency planning within its emergency response procedures. During emergencies that affect multiple agencies, MIPL(C)L works with the Province of Saskatchewan and participates in the Saskatchewan Emergency Plan. Under this Plan, contingency planning is the responsibility of the Provincial Emergency Management Committee. Although MIPL(C)L’s documentation mentions the need for contingency planning and notes ICS requirements for contingency plans, the company did not provide a process for the structured development of contingency plans that may become necessary when a successful response is jeopardized by abnormal or unforeseen events or circumstances that may arise during an emergency situation. As a result of the assessment, the Board has determined that MIPL(C)L is in non-compliance with OPR s. 6.5 (1)(t). The Board requires that a CAPA Plan be developed to address this non-compliance. |

||

Topic: CSA Z662-15 10.5.2 Pipeline Emergencies |

||

Regulatory Requirement: OPR s. 4 (1): When a company designs, constructs, operates or abandons a pipeline, or contracts for the provision of those services, the company shall ensure that the pipeline is designed, constructed, operated or abandoned in accordance with the applicable provisions of

|

||

Criteria Element 1: CSA Z662-15 – 10.5.2 Pipeline emergencies, clauses 10.5.2.1, 10.5.2.2, 10.5.2.3, 10.5.2.4 |

||

Assessed Area: The outputs of the process as related to the development and maintenance of Emergency Management Manuals, contingency plans and Emergency Management exercises |

||

Item Number |

Indicators of Compliance |

Assessment |

|---|---|---|

AP-12 |

CSA Z662-15 – clause 10.5.2.1 Operating companies shall establish emergency procedures that include a) procedures for the safe control or shutdown of the pipeline system, or parts thereof, in the event of a pipeline emergency; and b) Safety procedures for personnel at emergency sites. Note: Appropriate emergency procedures related to the pipeline, as determined in conjunction with community agencies, should be included. CSA Z662-15 – clause 10.5.2.2 Operating companies shall regularly consult and inform the public and agencies to be contacted during an emergency (e.g., police and fire departments), as appropriate, about the hazards associated with its pipelines. Note: If community emergency response plans exist, appropriate methods to consult and inform the public can be determined in conjunction with the community agencies. CSA Z662-15 – clause 10.5.2.3 Operating companies shall prepare an emergency response plan and make relevant sections or information therein available to local authorities. Note: CAN/CSA-Z731 should be used as a guide for the preparation of emergency response plans. CSA Z662-15 – clause 10.5.2.4 Operating companies shall have verifiable capability to respond to an emergency in accordance with their emergency procedures and response plans and shall demonstrate and document the effectiveness of such procedures and plans. |

No Non-Compliances Identified. |

Assessment Notes |

||

AP 12-a) Emergency Shutdown Procedures For the purposes of this audit, the Board verified that MIPL(C)L has emergency procedures that include the safe control or shutdown of the pipeline system, or parts thereof in the event of an emergency. These procedures include safety procedures for personnel located at emergency sites. MIPL(C)L indicated that its staff are trained to respond to emergency events on the provincial gas distribution system as well as the transmission facilities. Given that the scope of the audit focused on the identification and control of hazards, it should be noted that, the adequacy and effectiveness of these procedures were not included in the review. L’Office a vérifié par l’examen de la documentation et des entrevues avec des représentants de la société que cette dernière mettait à la disposition des autorités locales les sections ou les renseignements pertinents des manuels d’intervention d’urgence. Les manuels et les renseignements sont fournis par voie électronique ou en format imprimé par l’entremise d’un système contrôlé afin d’assurer que l’information diffusée est à jour. AP 12-b) Consulting and Informing public agencies / Availability of EM Plans During the audit, MIPL(C)L stated that, through its affiliation with SaskEnergy/TransGas it regularly consults with and informs the public and agencies to be contacted during an emergency (e.g., police and fire departments) about the hazards associated with its pipelines. It indicated that these activities are primarily managed and implemented as part of the Public Awareness Plan administered by SaskEnergy/TransGas. The plan includes consultation and training with agencies that may be involved during an emergency. The Board verified through a review of documentation and through interviews with company representatives that the company makes relevant sections of the Emergency Response manuals or information therein available to local authorities. Manuals and information is provided digitally and/or hard copy through a controlled system to ensure current information is provided. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. AP 12-c) Emergency Response Exercises During the interviews, MIPL(C)L stated that the company regularly verifies its ability to respond to an emergency using various types of exercises including table tops and full mock exercises. These exercises are used to assess the ability to respond as well as the suitability of the procedures and response plans. Although the majority of the exercises were conducted on the provincially regulated distribution system, documentation provided during the audit indicated that two of the thirty tabletop exercises and two simulation exercises were completed in 2016/2017 that were specific to the MIPL(C)L assets. It was also noted that a mock exercise is scheduled to be completed for MIPL(C)L in 2018 as well. Based on the review conducted and considering the scope of this audit, the Board did not identify any issues of non-compliance in relation to this requirement. |

||

Appendix II : NEB Purpose and Audit Framework

The NEB’s purpose is to promote safety and security, environmental protection, and efficient energy infrastructure and markets in the Canadian public interest within the mandate set by Parliament in the regulation of pipelines, energy development and trade. In order to assure that pipelines are designed, constructed, operated and abandoned in a manner that ensures: the safety and security of the public and the company’s employees; safety of the pipeline and property; and protection of the environment, the Board has developed regulations requiring companies to establish and implement documented management systems applicable to specified technical management and protection programs. These management systems and programs must take into consideration all applicable requirements of the NEB Act and its associated regulations. The applicable Legislation and Regulations which come under the NEB’s mandate, responsibilities and powers include:

- National Energy Board Act and associated regulations;

- Canada Oil and Gas Operations Act and associated regulations;

- Canada Petroleum Resources Act (sections 28 and 35) and associated regulations;

- Oil and Gas Operations Act and associated regulations; and

- Petroleum Resources Act and associated regulations.

Additional regulatory requirements are contained within:

- The Canada Labour Code, Part II, and the Canada Occupational Health and Safety Regulations; and

- Any conditions contained within applicable certificates or orders issued by the Board.

To evaluate compliance with its regulations, the Board audits the management system and programs of regulated companies. The Board requires each regulated company to demonstrate that they have established and implemented, adequate and effective methods for proactively identifying and managing hazards and risks. The Board’s management system requirements are described within the National Energy Board Onshore Pipeline Regulations (OPR), sections 6.1 through 6.6.

Background

The NEB expects pipeline companies to operate in a systematic, comprehensive and proactive manner that manages risks. The Board expects companies to have effective, fully developed and implemented management systems and protection programs that provide for continual improvement.

As required by the OPR, companies must establish, implement and maintain effective management systems and protection programs in order to anticipate, prevent, mitigate and manage conditions that may adversely affect the safety and security of the company’s pipelines, employees, the general public, as well as the protection of property and the environment.

During the audit, the Board reviews documentation and samples records provided by the company in its demonstration of compliance and interviews corporate and regionally based staff. The Board also conducts separate but linked technical inspections of a representative sample of company facilities. This enables the Board to evaluate the adequacy, effectiveness and implementation of the management system and programs. The Board bases the scope and location of the inspections on the needs of the audit. The inspections follow the Board’s standard inspection processes and practices. Although they inform the audit, inspections are considered independent of the audit. If unsafe or non-compliant activities are identified during an inspection, they are actioned as set out by the Board’s standard inspection and enforcement practices.

After completing its field activities, the Board develops and issues a Final Audit Report. The Final Audit Report outlines the Board’s audit activities and provides evaluations of the company’s compliance with the applicable regulatory requirements. Once the Board issues the Final Audit Report, the company must submit and implement a Corrective Action Plan to address all non-compliances identified. Final Audit Reports are published on the Board’s website. The audit results are integrated into NEB’s risk-informed lifecycle approach to compliance assurance.

Audit Objectives and Scope

This audit evaluated the company against the legal requirements and scope outlined in the main body of the audit report.

Audit Activities

On October 13, 2017, the Board informed TransGas/SaskEnergy (Many Islands Pipe Lines (Canada) Limited) of its intent to audit. Board staff then provided TransGas/SaskEnergy (Many Islands Pipe Lines (Canada) Limited) with an overview of the NEB audit process, the audit criteria, a request for documentation and a list of questions to answer relevant to the objectives and scope of the audit. The NEB conducted its assessment based on the responses provided by the company and the evidence gathered during the audit.

Board staff was in contact with company staff on a regular basis to arrange and coordinate this audit. TransGas/SaskEnergy (Many Islands Pipe Lines (Canada) Limited) established a digital access portal for Board staff to review documentation and records.

On 11 December 2017, Board Staff conducted an opening meeting with company representatives in Regina to confirm the Board’s audit objectives, scope and process. Subsequent to the opening meeting, interviews were held at the company’s office in Regina on 11-12 December 2017.

Throughout the audit, NEB staff provided company representatives with daily summaries, including action items where required.

On 9 February, 2018, the Board sent an audit pre close-out Information Request (IR) to the company. This IR outlined potential non-compliances identified during the audit. At that time the company was provided with the opportunity to present additional evidence to rectify these potential non-compliances.

On 13 March, 2018, the Board sent a close-out summary to the company representatives to present the assessment of findings noted during the audit.

Appendix III : Terminology and Definitions

The Board has applied the following definitions and explanations in measuring the various requirements included in this audit. They follow or incorporate legislated definitions or guidance and practices established by the Board, where available.

Adequate: The management system, programs or processes complies with the scope, documentation requirements and, where applicable, the stated goals and outcomes of the NEB Act, its associated regulations and referenced standards. Within the Board’s regulatory requirements, this is demonstrated through documentation.

Audit: A systematic, documented verification process of objectively obtaining and evaluating evidence to determine whether specified activities, events, conditions management systems or information about these matters conform to audit criteria and legal requirements and communicating the results of the process to the company.

Compliant: The company has demonstrated that it has developed and implemented programs, processes and procedures that meet legal requirements.

Corrective Action Plan: A plan that addresses the non-compliances identified in the audit report and explains the methods and actions that will be used to correct them.

Developed: A process or other requirement has been created in the format required and meets the described regulatory requirements.

Effective: A process or other requirement meets its stated goals, objectives, targets and regulated outcomes. Continual improvement is being demonstrated. Within the Board’s regulatory requirements, this is primarily demonstrated by records of inspection, measurement, monitoring, investigation, quality assurance, audit and management review processes as outlined in the OPR

Established: A process or other requirement has been developed in the format required. It has been approved and endorsed for use by the appropriate management authority and communicated throughout the organization. All staff and persons working on behalf of the company or others that may require knowledge of the requirement are aware of the process requirements and its application.

Finding: The evaluation or determination of the compliance of programs or elements in meeting the requirements of the National Energy Board Act and its associated regulations.

Implemented: A process or other requirement has been approved and endorsed for use by the appropriate management authority. It has been communicated throughout the organization. All staff and persons working on behalf of the company or others that may require knowledge of the requirement are aware of the process requirements and its application. Staff has been trained on how to use the process or other requirement. Staff and others working on behalf of the company have demonstrated use of the process or other requirement. Records and interviews have provided evidence of full implementation of the requirement, as prescribed (i. e. the process or procedures are not partially utilized).

Inventory: A documented compilation of required items. It must be kept in a manner that allows it to be integrated into the management system and management system processes without further definition or analysis.

List: A documented compilation of required items. It must be kept in a manner that allows it to be integrated into the management system and management system processes without further definition or analysis.

Maintained: A process or other requirement has been kept current in the format required and continues to meet regulatory requirements. With documents, the company must demonstrate that it meets the document management requirements in OPR, section 6.5 (1)(o). With records, the company must demonstrate that it meets the records management requirements in OPR, section 6.5 (1)(p).

Management System: The system set out in OPR sections 6.1 to 6.6. It is a systematic approach designed to effectively manage hazards and reduce risk, and promote continual improvement. The system includes the organizational structures, resources, accountabilities, policies, processes and procedures required for the organization to meet its obligations related to safety, security and environmental protection.

(The Board has applied the following interpretation of the OPR for evaluating compliance of management systems applicable to its regulated facilities.)