Watercourse crossings

We review how a project may affect the environment if a company is planning to cross a watercourse, such as a river, brook, or underground stream. We assess all watercourse crossings thoroughly.

Companies are required to follow all applicable guidance and regulations to protect watercourses during pipeline crossing activities. Effects of a project on an aquatic environment are part of an environmental assessment.

Canadian Energy Regulator Act approvals: The CER’s Filing Manual and Electricity Filing Manual outline the information the CER requires for assessments under the Canadian Energy Regulator Act.

Fisheries Act approvals: If a Fisheries Act authorization is required, the CER refers the information from the application about the how a project may affect fish and fish habitat to Fisheries and Oceans Canada.

When selecting a method for crossing a watercourse, companies consider geotechnical, economic, and other environmental factors. There are also provincial or territorial approvals where a project is being planned, such as those under provincial water acts.

Related documents

- Filing manual

- Electricity filing manual

- Memorandum of understanding with Fisheries and Oceans Canada

The aquatic environment

Habitat structure and cover

It is important that companies do what they can to reduce the effect a project may have on an area. For fish in particular, this may mean making sure that the land is put back as close as possible to how it was before the company started.

For example, when a company completes construction, the type of material it puts back should be the same as before. Beds and banks should also slope at the same angle. The vegetation covering the river or stream at the edge of the stream should also be returned to whatever it was before.

Sediment concentrations

Increased sediment poses the greatest risk to the productive capacity of a watercourse. It can be particularly harmful to fish egg incubation. Timing windows are determined for each watercourse based on the life cycles of the species present to reduce risks during the most vulnerable stages of life for fish. Timing windows tell companies when they should avoid working within a stream in order to best protect fish and fish habitat.

For example, for a fish species that uses River A to spawn (lay eggs) and for when eggs are developing in the gravel of a stream bed, the timing window will specify that no work should be done in River A during that time.

Water temperature

As companies are doing work, they need to take steps to prevent their activities from affecting the temperature of the water. Even the smallest change in temperature might affect how aquatic plants and animals grow and thrive. For example, many species of fish lay their eggs at a certain temperature. A change in temperature could affect their ability to reproduce.

Fish migration

When work is done around a watercourse, it is important that a company plans around sensitive times of year for aquatic life. For example, some fish, such as salmon, need to be able to travel up a watercourse to spawn. These migrations happen around the same time of year every year. Companies take measures to prevent their activities from interfering with fish migration.

Watercourse crossing methods

The two primary watercourse crossing methods are trenched and trenchless.

Trenched watercourse crossings

Trenched watercourse crossings involve digging a trench through a flowing watercourse.

What they are

Trenched crossings involve digging a trench through a flowing watercourse. There are two main ways this can be done: with an isolated trenched crossing or a wet-open cut crossing. The vast majority of trenched watercourse crossings are isolated trenched crossings. Wet open-cut crossings are rare.

- Isolated trenched crossings: High volume pumps, dams, culverts, or other methods are used to temporarily divert stream flow around the trench excavation and pipe installation. The main stream flow may run beside its usual stream bed for a short period of time so that the trench can be dug without additional sediment being added to the flowing stream.

- Wet open-cut crossings: The pipe trench is excavated and backfilled with a backhoe or dredging equipment in the stream channel. These installations are done in a flowing stream. They typically result in some degree of short-term, increased sedimentation downstream. Wet open-cut crossings are used only when other options are not feasible, as they generally result in a higher impact on the environment. This impact is usually temporary. If used, a company will often try and use this technique in frozen conditions or when water levels are low.

Steps

- Site preparation – Includes right-of-way surveying, clearing, and possible diversion of the watercourse. Pumps divert water around the isolated area (called a clean water bypass) to maintain natural downstream flows and prevent upstream ponding.

- Timing – Typically when stream flows are at seasonal lows to minimize effects on water quality, plant and animal life.

- Construction – Includes trench excavation, laying, and ditch backfilling. These are all often done within a single day. Before the construction area is de-watered, fish are rescued from within the isolated area and returned to the watercourse immediately downstream of the worksite. The construction area is then de-watered, excavated, the pipe is laid in place and the trench is backfilled.

- Reclamation – Reclamation is done to stabilize the disturbed vegetation along the area and restore banks. This includes restoring the stream bed and riverbank area, as required. Once the bed and banks of the watercourse are re-established, the diversion is removed and water is returned to the channel.

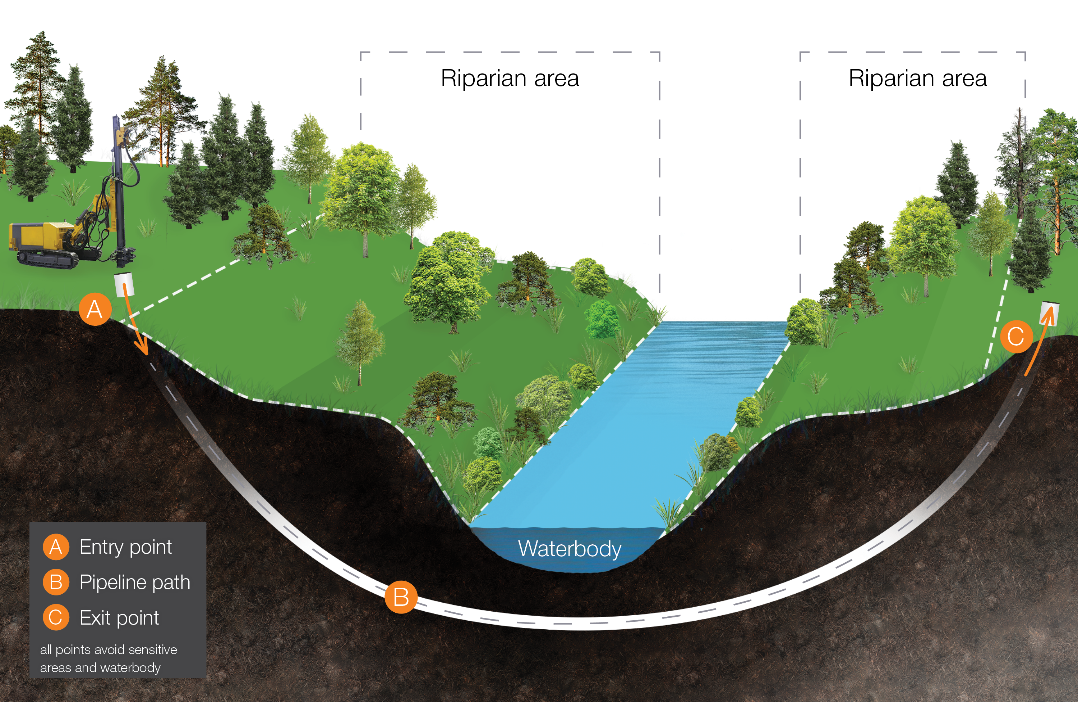

Trenchless watercourse crossings

Trenchless watercourse crossings may use horizontal directional drilling to avoid environmentally sensitive areas.

What they are

Trenchless watercourse crossings:

- require limited or no in-stream construction

- cause little to no disturbance to the watercourse bed and banks

Most common type: a horizontal directional drill

Benefits: A horizontal directional drill avoids disturbing congested or environmentally sensitive areas, such as large or sensitive waterbodies.

Steps

- A horizontal directional drill starts with pilot hole being drilled along the predetermined drill path.

- The drill string is pulled back through the bore hole to enlarge the diameter of the drill hole.

- Pipe is welded into a string that is slightly longer than the length of the drill and is coated with abrasion resistant covering and pretested to ensure pipeline integrity.

- Once the bore hole has been widened to the appropriate diameter, the pipe string is pulled through.

When a trenchless method may be used

Not all watercourse crossings are good candidates for a trenchless crossing method. Before deciding to use a trenchless method, it is important that a company consider factors, such as:

- the width of the channel

- the topography of the river valley

- suitable locations for entry and exit pads

- disturbance associated with the pads

- pipe bending radius

- stresses associated with pulling the pipe through the drill bore

- geotechnical conditions

- site reclamation prospects

- relative lifecycle costs

In some cases, trenchless crossings are not used because the soil is not stable enough or the slope is too steep. If a trenchless crossing is attempted in an area with poor site conditions, the risks to the environment are greater than those posed by a trenched crossing method.

Compliance and enforcement

We check to make sure companies are meeting our requirements, from when a company first applies to when a project ends. The CER may conduct a field inspection during a watercourse crossing to see that the company’s plans and activities are protecting the environment. The CER will work with companies to modify plans and activities if needed.

For companies that aren’t meeting our standards and requirements, we’ll take steps to enforce them and bring the company back into compliance.

Learn more about how we verify compliance and enforce our requirements.

- Date modified: