Market Snapshot: Trends in In-Situ Bitumen Production

Connect/Contact Us

Please send comments, questions, or suggestions for Market Snapshot topics to snapshots@cer-rec.gc.ca

Release date: 2023-03-15

BitumenDefinition* produced from Alberta’s oil sandsDefinition* is either mined or produced from wells. Only shallow bitumen, up to 75 metres deep, can be produced by mining.Footnote 1 For mining, large shovels dig bitumen, along with the sand it is found in, out of the ground, and load it into large trucks to be hauled to a processing facility, where the sand and bitumen are separated. When bitumen is too deep to mine, producers drill wells to produce the bitumen. This is called in-situDefinition* production.

How bitumen is normally extracted using in-situ production

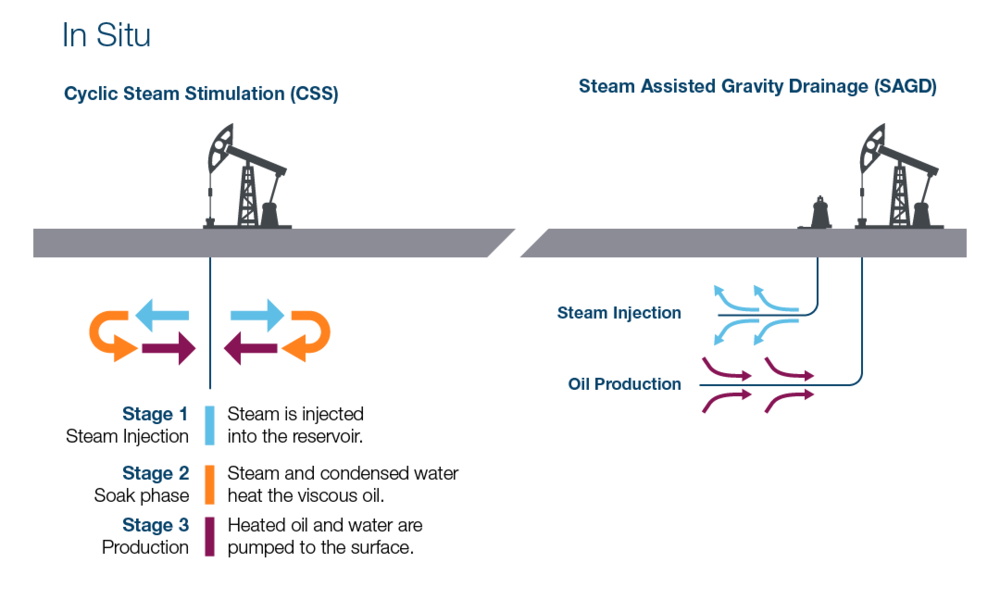

Bitumen has the consistency of peanut butter at room temperature, but flows like oil at high temperatures. To heat underground bitumen for in-situ production, producers inject steam into the formation through a well. This is done using either cyclic steam stimulation (CSS) or steam-assisted gravity drainage (SAGD) technologies.

How CCS and SAGD work

CSS uses the same well to heat and produce the bitumen. The well injects steam into the formation before the steam is shut off and the bitumen and water (cooled steam) flow back into the well for the next few months. This process is repeated for years until the bitumen reservoir is used up.

Figure 1: Diagram outlining how CSS and SAGD are used produce bitumen

Source and Description

Source: CER

Description: This diagram illustrates how CSS and SAGD are used to produce bitumen from the oil sands. CSS uses a single well to both inject steam into the bitumen containing reservoir and to produce the heated bitumen in a three-stage process. SAGD uses a pair of wells to produce bitumen. One well injects steam underground to heat the bitumen and the second well produces the heated bitumen.

SAGD technology uses pairs of long horizontal wells to produce bitumen. A steam injection well is drilled higher in the formation. A second well is drilled below the first well and close to the bottom of the formation, where it collects a mixture of bitumen and water, which flow downward because of gravity. Producers typically drill these wells in groups from a single location and can use dozens of CSS or SAGD wells to develop a single field in the oil sands. While CSS was the first technology used for in-situ production, most in-situ production now uses SAGD. SAGD is used more than CSS because it has proven to be more effective at producing bitumen in larger bitumen containing geologic formations.

A small amount of in-situ production does not use steam or heat. Some wells produce less viscous bitumen that can flow on its own. A small percentage of these wells inject solvents or other substances to help thin out the consistency of the bitumen. However, almost all in-situ production in the oil sands comes from injecting steam.

How steam-oil ratio measures project costs

Steam-oil-ratio (SOR)Definition* measures how much steam is used to produce bitumen. For example, a project with an SOR of three injects three barrels of water, as steam, into the reservoir to produce one barrel of bitumen. Steam is produced by boiling water in steam generators that burn natural gas. Thus, in-situ projects that have high SORs use more natural gas and have higher costs per barrel of bitumen, and vice versa. SORs can decrease over time if producers improve their technology or extraction processes. SORs can also increase if efficiency declines, or the producer begins to drill wells into reservoirs with less producible bitumen.

SOR trends in Alberta’s oil sands

Overall, the average SOR of Alberta’s in-situ production fell by 8.7% between 2010 and 2015 from 3.32 to 3.03, before leveling off and decreasing 0.5% more between 2015 and 2021 to 3.01.Footnote 2 SORs leveled off from 2015 to 2021 for all in-situ production, largely because the SORs of SAGD only slightly decreased while SORs of CSS projects rose by 28.9% from 2015 to 2021. Because far more bitumen is produced by SAGD than CSS, the average SOR slightly declined.

Figure 2: Average SOR for SAGD, CSS, and weighted average SOR for in-situ projects in Alberta from 2010 to 2021

Source and Description

Source: AER ST53: Alberta In-Situ Oil Sands Production Summary

Description: This line chart shows the average annual SOR by in-situ project type. The average SOR of in-situ projects decreased from 3.32 in 2010 to 3.01 in 2021, with the average SAGD SOR decreasing from 2.94 to 2.65, and CSS increasing from 3.83 to 5.17.

Trends in bitumen production type

In 2021, in-situ bitumen production averaged 1.66 million barrels per day, with SAGD producing 1.29 million barrels per day and CSS producing 0.21 million barrels per day. The remaining 0.16 million barrels per day of in-situ production are other technologies that do not use steam and are not used to calculate the average SOR. Oil sands mines produced an average of 1.59 million barrels of bitumen per day in 2021, while Canada averaged 4.91 million barrels of oil per day.Footnote 3

Greenhouse gas emissions in in-situ production

Because steam is created by boiling water using natural gas as a fuel, the SOR can be useful to estimate the carbon dioxide (CO2) intensity from each project. Multiplying a project’s CO2 intensity by barrels of bitumen produced can provide an estimate of total CO2 emissions from the project. About 1.7 gigajoules of natural gas are needed to create 1 cubic metre (6.2898 barrels) of steam from water, and produce roughly 150 kg of CO2.Footnote 4

While the greenhouse gas emissions per barrel of in-situ production fell from 2010 to 2020, total greenhouse gas emissions increased from 22.7 to 41.2 million tonnes of CO2 equivalent. This increase was because, despite producers becoming more efficient with steam injection, total bitumen production using steam rose from 0.76 million barrels per day to 1.50 million barrels per day, meaning more steam was used in total. Technologies such as carbon capture and storage are being evaluated to help lower in-situ emissions.Footnote 5

Figure 3: Relative change of in-situ bitumen production, steam generation and emissions from 2010 to 2020

Sources and Description

Sources: CER Estimated Production of Canadian Crude Oil and Equivalent, and Canada's Official Greenhouse Gas Inventory

Description: This chart shows the relative growth of in-situ oil sands production and their associated emissions and steam production. Between 2010 and 2019, in-situ production more than doubled, then dipped slightly in 2019 and 2020. In 2020, production was 97% higher than in 2010. Emissions rose at a similar rate between 2010 and 2020, although due to improvements in efficiency and SOR, the rise was slower. By 2020, emissions were 82% higher than they were in 2010. Steam production also increased alongside in-situ bitumen production and emissions. Between 2010 and 2020 steam production rose by 124%. While other indicators rose, emissions intensity, the number of emissions produced per one barrel of bitumen produced, fell by 8% between 2010 and 2020. Note: this chart only extends until 2020, the last year Environment and Climate Change Canada emissions data are available.

- Date modified: